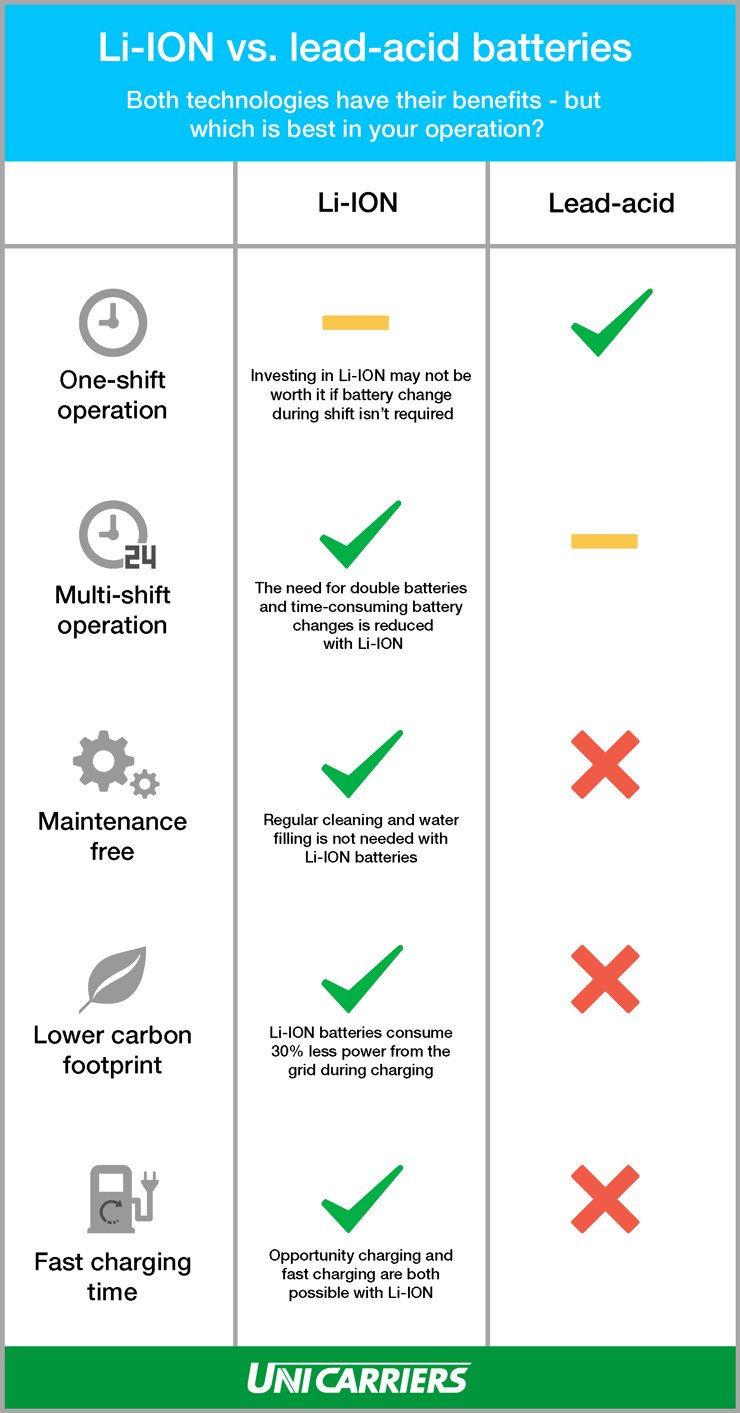

However for companies keen to implement this technology in their warehouses considerations must be made to ensure they have a dedicated battery charging area fitted with the necessary safety features to meet forklift charging station power requirements.

Forklift battery charger power consumption.

The correct charging system can extend your battery life and ensure that your power consumption is managed well.

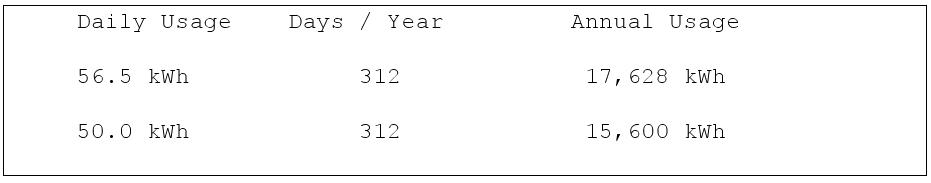

In this example a 40 kwh battery would provide the necessary power to complete the daily usage.

In a typical industrial electric forklift application with a 40 kilowatt hour battery the savings can be significant.

For example a customer replaced 60 chargers with high frequency units to maintain its 169 batteries.

You can review peak periods and drive the power to areas of demand without any ill affects to your battery fleet.

The majority of facilities using electric forklifts currently power their batteries with chargers using.

Therefore facility operators can benefit from increasing forklift battery charger efficiency.

Forklift battery chargers are usually sized at 14c to 20c or 14 to 20 of battery amp hour capacity.

Our goal is to increase the productivity of your forklift fleet.

Supporting the battery is the best way to keep your forklift fleet running efficiently.

Crown battery can conduct a power study that will give you a sample of the amount of power consumption per day.

Most industrial customers pay an average of 0 15 cent per kilowatt hour used when the utility pricing is averaged.

Since you have to put more power in the battery due to energy loss you have to put 48kw in to get the battery back above 80 charge.

Monthly lease cost of a forklift s battery and charger in the client example of 167 hours per month over a five day workweek the daily usage of approximately eight hours yields a 24 to 32 kwh usage by the electric lift truck.

It is important to know the ah rating of your battery if you aren t replacing an existing charger or to check if the existing charger is sized correctly.